Intelligent Control for Mechanical Rappers

NWL’s years of experience designing electrostatic precipitator control systems culminated in the Graphic Rapper Control (GRC), the most versatile rapper controller in the industry. The rapper control is utilized on an electrostatic precipitator to control the sequencing and the intensity of precipitator cleaning devices, (rappers). The GRCs microprocessor can automatically switch to one of 5 pre-set programs, based on boiler operating conditions or time of day. The system also has numerous features which enhance particulate removal efficiency, prevent particle re-entrainment, and provide valuable diagnostic and troubleshooting information. NWL’s GRC system also has the capability to operate most known rappers, vibrators, and tumbling hammer motor drives.

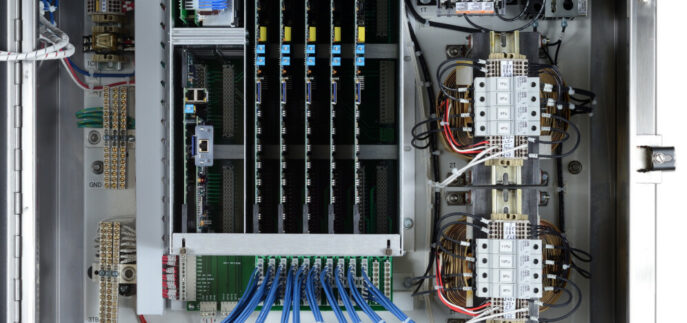

The GRC consists of three major components:

- Smart CPU (S-CPU) – offers support for 1,024 rappers, power-off rapping, trending, anti-coincidence grouping – making it the most powerful rapper controller in the industry.

- Smart Rap (S-Rap) – is controlled by the S-CPU. When the S-CPU has control, the S-Rap will energize up to 16 rappers and monitor current levels for alarm conditions. In the event of S-CPU failure, the S-RAP will continue to function until the controller is repaired or replaced.

- Global Display Unit (GDU) – is a 7″ color touchscreen in an IP65 package. It runs the Windows™ CE operating system in the background with NWL proprietary software designed to act as an operator interface for the rapper controller. Refer to the Global Display Unit Product Data Sheet for more details.

Additional features include:

- Ramped Intensity Pulse Rapping (RIP/RAP) – NWL’s patented RIP/RAP feature applies a series of raps with increasing force to more efficiently clean collector plates. The first rap is low energy, loosening the dust layer at the top of the plate. By gradually increasing the intensity of the raps in very quick succession, the layers are sequentially dislodged and agglomerated as they drop into the ash hopper. This procedure both improves particle removal and minimizes the potential for re-entrainment.

- Anti-Coincidence Grouping – programmable feature that will prevent simultaneous firing of rappers located serially to gas flow. The program will fire the lowest number rapper in the sequence; the others will fire in succession after a timed delay. This eliminates opacity spikes due to poorly coordinating rapping sequences.

- Opacity Spike Detection – correlates sudden increases in opacity with rapper operation to track and identify inefficient rappers. This is a very useful troubleshooting tool for ESP operators to diagnose upset conditions. Requires 4-20 mA signal from opacity monitor and 2 parameter inputs (time from ESP to monitor and % spike) to the program.

- Power Off Rapping/Reduced Power Rapping (POR/RPR) – the system can send a signal to the ESP voltage controller to de-energize (Power Off Rapping) or decrease (Reduced Power Rapping) T/R secondary voltage in the corresponding field prior to rapping. This feature improves ash removal and minimizes re-entrainment.

- R-Scan – diagnostic function that periodically sends a small energy pulse to each rapper to check for proper response. Allows user to conduct 100% test of all rappers within minutes.

- Automatic Program Control – 5 separate rapper programs can be loaded into the GRC. Program will automatically change based on boiler load or time of day. If no input is received, default program is activated.

- Auto Lift Calibration – the resistance of a magnetically activated rapper increases at higher temperatures, thereby reducing its intensity. Normal wear and tear also takes its toll on these devices. This feature enables the user to set the desired rise in inches, so that there is no need to adjust rapper lift with changing weather or aging conditions.